ASSALAMUALAIKUM..AND..HELLO TO ALL READERS

HANDSOME MR SHAMAN

BEAUTIFUL MRS WAN NADIAH

Before that, let us introduced our group members

LASTLY......

|

| FARAH |

INTRODUCTION

A bioreactor is a vessel in which is carried out

a chemical process which involves organisms or biochemically active substances

derived from such organisms

Bioreactors

are commonly cylindrical, ranging in size from some liter to cube meters,and

are often made of stainless steel.

Bioreactor

design is quite a complex engineering task. Under optimum conditions the

microorganisms or cells will reproduce at an astounding rate. The vessel's

environmental conditions like gas (i.e., air, oxygen, nitrogen, carbon dioxide)

flowrates, temperature, pH and dissolved oxygen levels, and agitation speed

need to be closely monitored and controlled.

METHODOLOGY

Preparation of media and reagents

1.Yeast extract,

peptone and glucose is weighed in the ratio of 3:1:1 and is added into a flask.

2.300ml of

distilled water is added.

3.The solution is

stirred until homogeneous solution is obtained.

Figure 1

5.The media is autoclaved at 121oC

with 15 minutes retention time.

6.The flask is

stored in an incubator shaker under the conditions of 200rpm and 30oC

overnight.

Setting up

bioreactor

1.The bioreactor is cleaned with distilled water to remove any residue

from previous usage.

2.Upon cleaning, the orifice of the sparger is inspected for any

blockage by running water through the air sparger tubes. (figure 2)

Figure 2

Figure 2

3.The agitator and agitator driver is lubricated using glysol solution until the lubricant flooded at the top of the drive.

Figure 3

4.The bioreactor is assembled. Glass vessel is connected to the base unit, lifting with the handles of the support frame and the stud is placed at the back of the vessel into the metal fork on the support frame.

5.The drive arm is

lowered into the horizontal position.

6.The side shield

is replaced to keep it out together with the base unit.

7.The exit gas

cooler is fit into a free port and the water connecting tubing is checked for

length and connections are made ready for the next day.

8.The pO2

electrode is located and the green plastic end cap is removed. The bottom metal

section is unscrewed and the membrane cartridge inside is checked whether has

liquid electrolyte in it. If not, up to half is topped from the bottle

provided.

9. The pO2

electrode is fit into the vessel loosely. The top plastic cap is removed from

the electrode.

10. the connection

point between the vessel and head plate is smeared with high vaccum grease

(figure 4).

Figure 4

11. All internal part of the bioreactor(vessel, sparger, impeller, agitator and head plate) is sprayed with alcohol solution (figure 5). The head plate and vessel is then connected.

Figure 5

12. Two reagent

bottles are prepared (anti-foam and base). Anti-foam is poured into one of the

reagent bottles while the one for the base is filled with distilled water prior

to autoclave.

13. Yeast extract:

Peptone: Glucose (YEPG) medium is prepared with the same ratio of 3:1:1 and

distilled water is added until the volume reaches 900ml. The medium is then

added into the vessel.

14. All openings,

filters and pump are wrapped with aluminium foil and all tubings are clamped

before autoclave. (Figure 6)

Figure 6

Inoculation into the media and fermentation.

1. After

autoclaving, all aluminium foil is unwrapped and all clamps are removed.

2. Base is filled

into the reagent bottles and both the pumps of the reagent bottles are fitted

to the correct motors and the tubing connected to the multi-way inlet and

clamped closely. (figure 8)

Figure 8

3. Temperature, pH and pO2 electrode are fitted into the vessel and are calibrated.

4. Inoculum is

poured into the vessel under aseptic condition.

5.Speed is

adjusted to 300rpm and cascade, pH and pO2 are all on. Fermentation

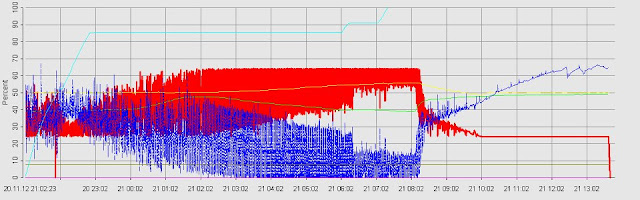

is run and the sample is collected every 2 hours. (figure 9)

RESULT

Times

|

OD

|

Blank

|

0.000

|

3.30pm

|

0.148

|

5.30pm

|

0.793

|

7.30pm

|

0.803

|

9.30pm

|

0.824

|

11.30pm

|

0.811

|

1.30am

|

0.940

|

3.30am

|

0.934

|

5.30am

|

0.901

|

7.30am

|

0.324

|

9.30am

|

0.171

|

RESULT OF GLUCOSE READING

TIME

|

CONDITION

|

READING (mg/dl)

|

3.30pm

|

267

|

|

5.30pm

|

246

|

|

7.30pm

|

226

|

|

9.30pm

|

Diluted

|

182

|

11.30pm

|

Diluted

|

Low

|

1.30am

|

Diluted

|

Low

|

3.30am

|

Diluted

|

low

|

5.30am

|

Diluted

|

low

|

7.30am

|

Diluted

|

Low

|

9.30am

|

Diluted

|

low

|

DISCUSSION

The

inoculum that used in the experiment was 150ml of YEPG, 1% yeast extract

(10mg/ml), 2% peptone (20mg/ml) and 2% glucose (20mg/ml). While the culture

medium used was 10 times of the materials that used to prepare the inoculum.

According to the results of my group

obtained, the OD of the yeast (Saccharomyces cerevisiae) was showing increased

from 0 hour (OD= 0.148) to 10 hours (OD= 0.940), this indicated the log phase

of the yeast cells. After 10 hours growing, the yeast cells were reached the

stationary phase from 10 hours (OD= 0.940) until 14 hours (OD= 0.901). After

the stationary phase ended, the yeast cells were reached the death phase in

which the OD was sharply decrease from 0.901 to 0.321 and finally reached

0.171. The growth curve of any organisms including the yeast cells that we used

in this experiment- Saccharomyces cerevisiae are following the sigmoid curve,

which start from lag phase, log phase, stationary phase and finally reach the

death phase.

From

the results we also can see that the glucose concentration in the culture

medium was gradually decreased from 267mg/dl to low concentration

(undetectable). This is because the yeast cells required the glucose as the

substrate to carry out aerobic fermentation to increase the biomass. Depleted

in the glucose will decrease or stop the growth of yeast.

Alkali was used in the experiment because

need to regulate and maintain the pH of the medium at pH 6, which is slightly

acidic condition. Due to the production of acetic acid during the aerobic

fermentation by the yeast, the pH of the medium will dropped to below 6, the

unsuitable and too acidic pH will affected the yeast growth, thus the alkali

was playing the role in increase the pH of the medium back to pH 6, an optimum

pH for the optimum growth of yeast.

Anti foam agent was also been used in the

experiment, this is because a lot of foam will be produced during the

fermentation process, especially in the aerobic fermentation like we carried

out in this experiment. The role of this anti foam agent is to reduce the foam

formation in the culture medium. The foam will affect the yeast cells growth

and make the medium over flow from the vessel, results in the contamination and

waste of the product.

Because

the process of fermentation we carried out was aerobic, which mean that oxygen

was required to increase the yeast biomass, so the inlet air was needed to pump

into vessel to succeed the fermentation process. 3.3vvm was the level that we

used in the experiment in order to pump in the sufficient amount of oxygen into

the medium for yeast consumption. The inlet and outlet air were required filter

(the pore sizes were 0.2 nanometer) to filter out the microbes normally made up

of bacteria and fungus from entering into the vessel which will cause

contamination and escaped out to the surrounding air. Exit air cooler was used

to condense back the medium which had been evaporated back into the vessel,

this is to prevent the excess products loss, even though the efficiency of the

cooler is around 95%. Insufficient in oxygen will lead the yeast to carry our

anaerobic fermentation, which convert the glucose into bioethanol, no biomass

will produce.

The speed of agitation applied during the

shake flask culture will influence the maximum growth rate of the yeast when

cultured in the bioreactor. The faster the speed of agitation during the shake

flask culture (300rpm), the faster the yeast increase in the biomass. If the

rpm was at 200 during the shake flask culture, the yeast will show slow growing

when cultured in the bioreactor which the speed of the impellers also

maintained at 200rpm. This is due to the insufficient obtained in the oxygen

and also glucose by the yeast to achieve optimum growth.

The optimum temperature for the yeast to

grow is 30 degree celcius. The heat will be produced during the aerobic

fermentation, which the temperature of the medium will increase. Unsuitable

temperature will affect the yeast growth, so the jacket water inlet is required

to regulate and maintain the medium’s temperature at 30 degree celcius.

CONCLUSION

The setting up of bioreactor needed

to be done carefully to ensure smooth and successful fermentation process.

Aseptic technique is vital to ensure maximum yield of product by preventing

contamination. At the end of this experiment, better understanding on

bioreactor operation was obtained and experiences were gained for the handling

of bioreactor during fermentation process.

REFERENCE:

1.

1.Transgalactic Ltd, 2005. What Is Bioreactor?. [online] Available

at: <http://www.bionewsonline.com/o/what_is_bioreactor.htm]. [Accessed 5

November 2012 ]

THANK YOU........

Nice writing, Thank you, guys :)

ReplyDelete